MIT PLATE HEAT EXCHANGERS

General Features / Plate Heat Exchanger Technology

MIT Plate Heat Exchangers, the rising star of Plate Heat Exchanger market, takes heart from the design team which gives continuous support. In Plate Heat Exchanger Market, all technologies have become ordinary. On the other hand, Ekin Endüstriyel design team proving that still there is something to do something new, will make new studies and show what can be done for the market.

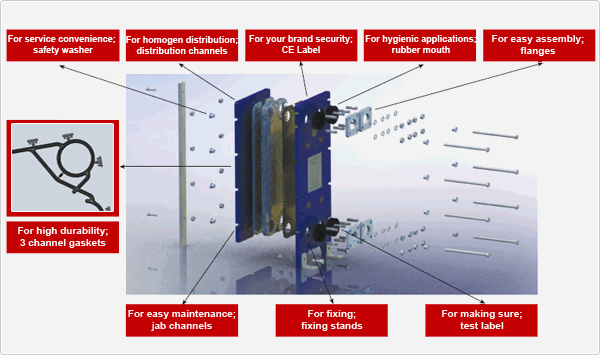

With three channels gasket system, higher performance;

Triple Flexible Pressing Channels: In contrast to planar pressing surface placed on standart gaskets, it is possible to prevent permanent deformation on the main gasket with the help of three different symmetric pressing surfaces. It decreases permanency of the deformation on the channels with the help of elasticity of the channels, so you do not need to change the gaskets ,even though you lay up the heat exchangers over and over again.Thin Section Pressing Surface: In Plate Heat Exchangers,in standart gaskets, the surfaces pressing the former plate are in thick section. Thin section pressing surface splits from gastkes' upper faces in the shape of V, presses front plate with thin section, causes surface extension and so provides high pressure resistance.

Colorful Auricle: There are colors in gaskets specifying material of the gaskets in all Plate Heat Exchangers. In standart gaskets, these colors are determined after production by painting gasket surface. In long term usage of the gaskets, because of liquid corrosion and outside air condition, these colors disappear and after sometime it becomes impossible to recognize material of the gaskets. In MIT Plate Heat Exchangers, one of the fixing auricles is made of fully colorful material so no matter how much corrossion occurs in the gaskets, it is possible to find out material of the gasket.