MIT APARTMENT AND LOCAL HEATING NETWORK TRANSFER STATIONS

General Features / Components Which Compose

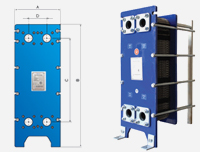

HEAT EXCHANGER :

The exchanger which is situated within the station, provides the domestic hot water obtained through passing the hot water coming from boiler room from the exchanger and heating city water.Plate exchangers are devices that work based on generating heat transfer principle between two different fluids which have temperature difference.

They are completely separated from each other with fluid plates which will heat and fluid plates which will be heated. Plate exchangers in transfer station applications; are the main equipments for domestic hot water.

THERMOSTATIC MIXING VALVE :

Thermostatic valve provides the domestic hot water, obtained by heating the cold water coming from city line in the exchanger, to go to the taps at the constant temperature. Besides, as temperature value can be regulated to the preferred level, boiling because of overtemp water reached to the tap is prevented.Moreover, as in floor heating systems, hot water coming from the central boiler room is not wanted to go directly to the floor heating line, the temperature is fixed at the required value with thermostatic mixing valve.

IHPT THERMOSTATIC ROTARY VALVE :

When a usage in any flow at the mains line is subject, it orients the heating line to the exchanger in a proportional way according to the flow quantity.Through its thermostatic control, it can fix domestic hot water at a constant temperature. Thus, legionella bacteria and boiling risks on the taps are prohibited

CALORIMETER :

It calculates the fair fuel consumption regarding each flatís usage quantity through calculating thermal loss of hot water coming from central boiler room in the exchanger and within the flat, and thanks to the M-BUS system, it is possible to monitoring, billing, even limiting the usage from a single center.ROOM THERMOSTAT :

The motorized valve within the station is controlled in such a way that provides comfort temperature in the flat thanks to the room thermostat, the flow rate of the hot water coming from the central boiler room is regulated proportionally with room thermostat control and extra saving and ease of use is provided in our economic system.THERMOSTATIC VALVE :

Thermostatic valve provides the domestic hot water, obtained by heating the cold water coming from city line in the exchanger, to go to the taps at the constant temperature.Besides, as temperature value can be regulated to the preferred level, boiling because of overtemp water reached to the tap is prevented. It provides proportional work without the need for an external energy.

DIFFERENTIAL PRESSURE (AP) CONTROL VALVE :

It is used in order to control the differential pressure at the radiator line.One of its functions is; through generating an extra pressure in the radiator line according to the exchanger line, to orient the heating water to the exchanger when consumption occurs in the domestic water line. Thanks to this AP controlled valve, a parallel work between radiator and exchanger is provided. Thus, all the system is balanced and inter-floor pressure differences are prevented.

PM REGULATOR :

When a usage in any flow at the mains line is subject, it orients the heating line to the exchanger in a proportional way according to the flow quantity. By controlling the pressure on the heating line, it performs sort of a balancing valve. When the use of hot water is ended, the flow from the central heating boiler room to the exchanger is interrupted and calcification in the exchanger is prevented.TEMPERATURE LIMITING VALVE FOR RETURN WATER :

It provides the hot water coming from the central boiler room rising at the constant temperature when it exists from the exchanger. Thus, high efficiency is provided thanks to the low return temperature. Moreover, it insures the exchanger to stay always hot by providing a standing flow within the exchanger.COLD WATER METER :

It calculates the use of the water coming from mains before being conducted directly to the exchanger and taps, and as there is no need for and extra space in the installation, space saving is provided and our heat station is made compact.Besides, consumption quantity can be read through the meter and it can be remotely read or billed with M-BUS system.

COLLECTOR GROUPS :

Before the hot water coming from the central boiler room is conducted to the heating line, it can be separated with delivery and return collector in order to have equal pressure in all the radiators within the flat. Including collector groups within the heat station, beside providing space advantage, removes the crowd at the flat entrance installation.EQUIPMENTS THAT CAN OPTIONALLY BE ADDED TO THE PROJECT :

- Cutting valve- Strainer

- Strainer at the mains water inlet

- Collector groups

- Room thermostats

- Hot water recirculation line and pump

- Thermostatic three-way mixing valve for floor heating

- Frequency controlled pump

- Cooling line

- Calorimeter

- Cold water meter

- Closed cabinet

STANDARD UNIT COVERAGE :

- Galvanized or stainless steel installation sheet- Plate exchanger

- Thermostatic valve

- Differential pressure (dP) control valve

- Rotary valves

+ IHPT Thermostatic Rotary Valve

+ Accelerator

+ PM Regulator