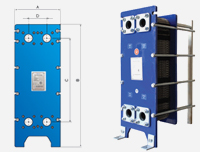

MIT PLATE HEAT EXCHANGERS

Area Of Usage / FOOD AND HYGIENIC APPLICATIONS

PLATE COOLERS:

Raw Milk Cooler (One / Double Level), Airan Cooler (Double Level), White Cheese Cooler (Regeneration)PLATE HEATERS:

White Cheese Heater, Kashkaval Cheese Heater, Yogurt and Milk Heater, C.I.P. Solution HeaterPLATE PASTEURIZATION SYSTEMS:

Drinking Milk Pasteurization, White Cheese Pasteurization, Kashkaval Cheese Pasteurization, Yogurt - Airan Pasteurization, Butter Pasteurization, Brine PasteurizationMilk Pasteurization:

Milk is one of the basic nutritions. Collecting ,producing and healthily keeping milk is a hard task. That's why different solutions have been tried along the history and lastly, pasteurization technology have been developed. In rough expression, pastorization is heating milk rapidly and cooling it again. By means of this process, all the bacterias in the milk are killed. MIT Plate Heat Exchangers are favourably designed for this process.The most important advantage of using plate heat exchanger in pasteurization is reaching high regeneration values. Milk is in a loop in the heat exchanger. By means of this, milk coming from heating and hot milk going to cooling part and cold milk going to heating collide in regeneration level and heat transfer occurs. With this energy and time saving system, the process is completed faster and cheaper. In multi level MIT Plate Heat Exchangers, it is possible to design hygienic in-out for equipments like seperator, homogenizer, holder and degasifier.These equipments are delivered ready to assemble.

Hygiene is vital for foods. That is why heatexchangers used for food applications are produced as stainless. Foods contact only with stainless surfaces and special gaskets that took FDA(Food and Drug Administration) certificate.

Yogurt-Airan Pasteurization:

After some process applied to milk , yogurt is obtained and just lilke milk, yogurt is a very suitable for bacterias to increase. That's why the same process applied to milk must be applied to yogurt too. MIT Plate Heat Exchangers with their large plates which are suitable for yogurt applications, have large gap and provide maximum performance for dense liquids, ensure providing best solution.

CIP Applications:

Hygiene is very important for processing milk and yogurt. Because these foods are exposed to bacterias. In these applications, the whole processing unit must be cleaned periodically to prevent bacteria formation. The liquid used for cleaning is called CIP. This liquid must be circulated in the system in certain temperatures and flowrates. MIT Plate Heat Exchangers are used for keeping CIP liquid in desired temperatures.