MIT PLATE HEAT EXCHANGERS

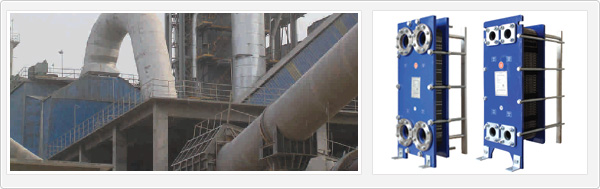

Area Of Usage / INDUSTRY

Cooling Rolling Press Oil:

In bloomeries, used oil gets hot and looses its lubricant function and so company performance goes down. To keep the bloomery oil in an optimum temperature, MIT Plate Heat EXchangers are used. With cooling tower, chiller circuit and a simple automation which are connected to Heat Exchanger's seconder circuit, rolling press oil stays desired temperature and your company works with maximum temperature.Cooling Borax Oil:

Borax oil is one of the corner stones of indusry, it is heart of the machining. Quality and temperature of borax oil is very important to get maximum performance from cutting edge and to reach maximum cutter life. If cooling tower or chiller is used with MIT Plate Heat Exchangers which enable you to keep borax oil in an optimum temperature, you can get maximum efficiency.

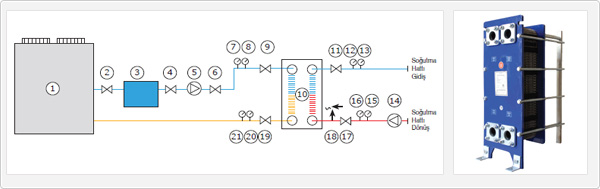

Cooling Group Cycle:

In today's world, cooling towers is the most common cooling source to meet the cooling demand in industrial facilities. These towers can be either open or close and in both, MIT Plate Heat Exchangers are used. In open towers, some amount of solid particles mixes with water so this water with particles can not be sent to system that will be cooled directly. By using MIT Plate Heat Exchangers between the system and the open tower, the system is seperated as two circuits and MIT Plate Heat Exchangers take the whole risk. In due course, if the heat exchanger gets dirty, it can be cleaned and so the system can work with the same performance again.

Chiller Group Circuit:

Generally, it is not enough using cooling tower in such situations that low temperature water needed. That's why chillers are preferred in that kind of applications. Because of that chiller groups are very sensitive , expensive devices and it is really hard to fix them, in a bad situation caused by the system, big damages may occur. MIT Heat Exchangers seperate the system and chiller circuit and so make them work free from each other, they just make heat transfer between them.Waste Heat Recycle:

In industrial facilities,there are a lot of heat sources that go in vain such as rotten steam, hot water that returns without washing the fabric. At the same time,there are some applications which require heat like utility hot water production and office heating. If you use MIT Plate Heat Exchangers to transfer avaliable heat sources to heat needed areas, you do not waste your heat and you do not have to pay extra cost for your heat requirement as well. Nowadays, the competition in production has been greatly increasing.The most important factor about relieving companies is to decrease expenses. Energy expenses is one of the most biggest components, it is very significant for eveybody so wasting it is unacceptable. If we make a rough calculation, a heat exchanger used for heat recycle will amortize itself in 3-6 months and start to make company profit.